May 31, 2021

Adopting Next Generation Telematics: “COVID-19 and Beyond”

New technology is revolutionizing the power of fleet management and enhancing the speed of productivity, and fleet telematics has the potential to completely transform waste and recycling companies. Real-time communication between back-office and drivers helps reduce fleet downtime as teams are able to work together effectively and efficiently with more clarity over maintenance requirements.

By Don Diego Padilla II

COVID-19 put waste collectors on the front lines on a struggle to keep up. Facing longer days, delayed maintenance work and rising costs, the haulers turned to fleet technology to meet rising demand. Migration to fleet technology helps simplify reporting, improve fleet safety and increase uptime. Waste and recycling companies are starting to understand that implementing smart technology will continue through to drive profitability and efficiency beyond the post pandemic recovery.

Unplanned downtime is costly for a business and frustrating for fleet managers. Waste and recycling businesses are constantly looking for ways to either upgrade their current technology or look for new fleet management solutions to increase optimal use of their collection fleets. Here are some ways that managers are leveraging the intelligence of telematics data to help reduce downtime and significantly help cut direct costs and increase ROI.

Reduce Maintenance Cost

Reduce Maintenance Cost

One way to begin putting money back towards your bottom line is by reducing maintenance costs while increasing each truck’s lifespan and time on the road. Ensuring a truck’s longevity is a top concern for fleet managers—truck repairs and damages for the most part may be preventable with the implementation of fleet telematics. By installing telematics on trucks, fleet managers and staff receive reports to track driving behavior— from excessive speeding, hard braking and aggressive driving that would contribute to the wear on trucks. Cost-saving features such as automatic alerts for engine diagnostics, idle time or necessary repairs and tune-ups allow fleet managers to be proactive in preventing additional maintenance costs.

Preventative Maintenance

COVID-19 forced many waste companies to look for new technology for accurate, real-time data to meet rising demand for services. The future of preventative maintenance technology gives drivers the tools to document and communicate exactly what is happening in the field in real-time, with pictures, audio, speech-to-text and video recordings. A preventative maintenance program helps solid waste management fleets keep their vehicles on the road, reducing unscheduled downtime and maximizing the productivity of vehicles and personnel. Fleets can save anywhere from 10 to 20 percent on maintenance costs with technology that gives fleet managers instant insight into truck and driver performance—from service history and preventative maintenance status, to warranty and truck build information—to help increase safety, efficiency and vehicle uptime. Real-time information in the hands of maintenance supervisors leads to less diagnostic time, faster repairs and overall shop efficiencies.

The future of fleet maintenance extends beyond the traditional fleet management solutions as demand for analytics rises. Properly maintained systems ensure that fleet owners always have access to a 360-degree view of each vehicle, its environment and its operating conditions. They also contribute to the ongoing safety of vehicle operators and others on the road to the peace of mind of operations supervisors.

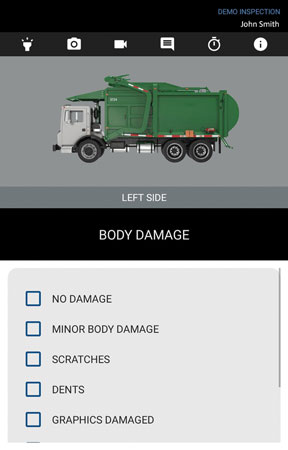

Pre/Post Trip Inspections

Vehicle inspection programs help to eliminate paper inspection forms, and supports any required inspection types for a more sophisticated automated inspection, resulting in enhanced maintenance and operational efficiency. Waste and recycling companies have access to automated pre/post-trip and maintenance inspections that are easy to use by downloading an App from the Google Play Store, and can customize their own inspections specific to their trucks. Digital inspection data is instantly available for maintenance, auditing and measuring results.

The challenge is finding customized preventative maintenance programs that fit the needs of waste and recycling industry as well as finding qualified technicians to diagnose and optimize truck performance based on main inspection results immediately forwarded to the maintenance shop.

We really felt the pain of our client drivers, fleet managers and maintenance teams during the peak of the pandemic. Our team introduced a great preventative maintenance and vehicle inspection program that helps relieve the stress of repair concerns and reduces cost and downtime for years to come. Advanced telematics provides quick, accurate and reliable business intelligence that can significantly improve efficiency while reducing the chance of human error. These tools help managers have better control of all their operations and respond to emergency situations quickly and effectively.

Vehicle inspection technology tightly integrated to the maintenance system via open architecture and public API, can drive even more efficiencies such as advance parts ordering, labor planning and automated warranty considerations.

Save Fuel Costs

Telematics can help waste and recycling companies save up to 20 percent on fuel costs. Tracking activity reports on each truck can help identify inefficiencies contributing to the higher cost. Implementing GPS tracking provides fleet managers with the ability to monitor activity of how collection trucks are being used via the engine control module (see unnecessary idling) and video recordings from cameras in the cab and around the vehicle. Supervisors can observe driver behaviors first-hand and recommend lasting improvements going forward. It is not uncommon for fleet owners that rely upon these types of solutions to slash as much as the equivalent of 30 minutes per route per day.

In today’s challenging times, it is important to consider the future of your waste and recycling collection business. How will you reduce cost? How can you increase ROI? How will your company meet the demands of growth and implemented social distance mandates?

Fleet Telematics and Data Analytics

According to Business Wire, fleet telematics systems are expected to grow by 38.8 billion USD, accelerating the market growth at a CAGR of almost 23 percent, with North America being the largest market and expected to continue growing upwards well into 2026. Results of telematics are:

1. Prioritizing road safety

2. Reducing carbon emissions

3. Reducing overall fleet management expenses

4. Save insurance costs

When fleet managers analyze telematics numbers and figures, they are looking to collect in-depth information to be able to put together a story on the performance of their fleet operations and business. Measuring performance overtime allows companies to uncover gaps and identify specific opportunities for improvement.

More than ever, fleet managers are looking to add more cameras to their fleets to improve safe driving behaviors, reduce distracted driving, provide coaching to drivers and avoid false claims with the help of video telematics. Fleet managers really want to help their drivers with actionable and accurate information in real-time. Our team has been responding to a growing demand for video telematics as companies look for ways to close the gaps between fleets, drivers and back-office. This can be life changing for many as it directly impacts the number of accidents and claims.

Revolutionizing the Power of Fleet Management

When adopting next-generation fleet telematics, communication between back-office and drivers will be seamless with no delays allowing fleet managers to connect with drivers without jeopardizing their safety. While drivers are on route, fleet managers are able to provide road and weather condition updates, emergency coaching, re-routing or assigning new routes with no downtime while increasing efficiency. New technology is revolutionizing the power of fleet management and enhancing the speed of productivity and fleet telematics has the potential to completely transform waste and recycling companies. Real-time communication between back-office and drivers helps reduce fleet downtime as teams are able to work together effectively and efficiently with more clarity over maintenance requirements. | WA

A waste industry fleet management veteran, Don Diego Padilla II is Vice President of Sales at FleetMind – a Safe Fleet brand, where he spearheads business and customer development activities. Safe Fleet is the largest fleet video supplier in North America with more than six leading video surveillance brands and integrated fleet safety management technologies to help cities work smarter and stay safer. Previously, Don Diego was a Regional Sales Director for Allied Waste (Republic Services), a leading provider of solid waste collection, transfer, recycling and disposal services in the U.S. His industry white paper on fleet safety garnered a Network Products Guide Award in the “Best White Paper” category. Don Diego has been published in numerous industry magazines and is a frequent speaker at industry forums such as Waste Expo, Fleet Management Expo, and regional municipal waste management events (e.g., SWANA). He can be reached at (770) 876-4507 or e-mail [email protected].